The TRI Article Exemption

- bcurtis08

- Aug 28, 2025

- 2 min read

Updated: Aug 29, 2025

One of the most confusing parts of the Toxics Release Inventory (TRI) program is the article exemption. On paper, it looks straightforward. In practice, it can be a trap for the unwary.

What Counts as an Article?

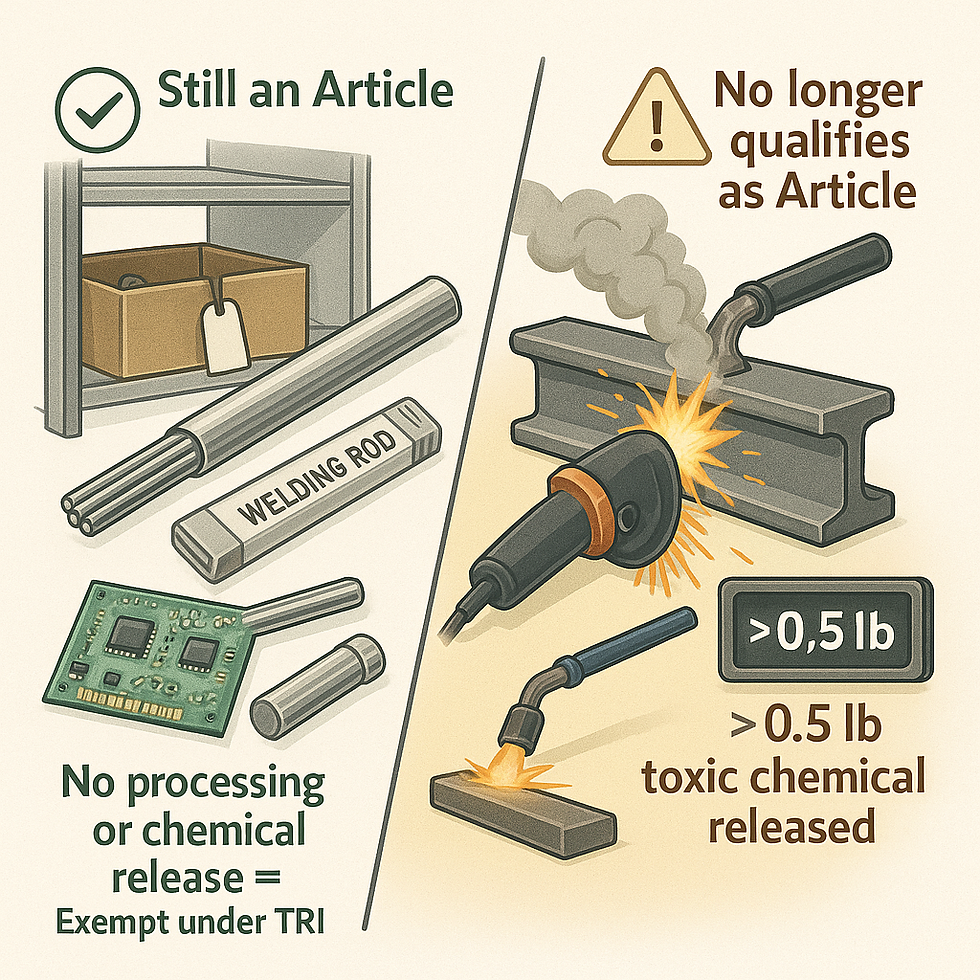

Under TRI, an article is exempt from threshold and release determinations if it is manufactured into a specific shape or design, its end use depends on that shape or design, and it does not release a listed toxic chemical during normal processing or use at the facility.

Retain Article Form

Notably, the exemption is preserved when an item continues to exist in its manufactured form without releasing a listed toxic chemical, even if the facility later discards it. The key is whether the item remains recognizable as the article. If it still exists in its manufactured form and does not release a listed toxic chemical during normal handling, the exemption is preserved. This applies whether the item is discarded, transferred, or kept in storage — as long as it is still identifiable as the article, it is not treated as a release. Once the item is altered so that toxic chemicals are emitted (through grinding, welding, combustion, or similar processing), it no longer qualifies and the exemption is lost.

The 0.5-Pound Rule

Even if an item meets the definition, there is a quantitative limit. If processing or use of “like” articles at a facility releases more than 0.5 pounds of a toxic chemical in a reporting year, the exemption no longer applies. This cut-off is measured in the aggregate. Once exceeded, reporting is required for all toxic chemicals in those articles.

Where Facilities Get Caught

Certain processes commonly cause facilities to lose the exemption:

Welding rods: By design they release toxic chemicals when used, so they are never articles.

Welded items: The joined metal pieces can remain exempt, provided they do not themselves release more than 0.5 pounds.

Circuit boards with lead film: If processing releases more than 0.5 pounds of lead in a year, the exemption does not apply.

Metal fabrication: Cutting, grinding, or heating that causes releases above 0.5 pounds triggers reporting.

The exemption can save a facility from unnecessary threshold calculations and reporting. But the margin for error is slim. A small welding or grinding operation on large volumes of alloy can push releases over the 0.5-pound limit before anyone notices. For compliance managers, the key is documentation and monitoring. Track releases closely, aggregate across all like items, and recognize when a process crosses the line from exempt article handling to reportable chemical release.

How TRI Toolkit Can Help

Manually tracking article exemptions across multiple product lines can be tedious. TRI Toolkit makes this process far more manageable by helping facilities:

Keep records of like items that are being treated as exempt.

Track usage and release data to support an exemption claim.

Provide expert guidance on EPA's article exemption rules to ensure the rule is properly applied.

Generate documentation to make the claim audit proof.

By organizing information in one place, TRI Toolkit gives facilities a clearer basis for claiming article exemptions and demonstrating how the criteria were met.

Comments